Waste Treatment Services

Foundry In-Line Waste Treatment System - Western Ohio

In 2012, Free Flow Technologies, LTD was contacted by a large Western Ohio foundry regarding our FF-100® reagent treatment product and an associated feeding system for the reagent. The foundry was dealing with environmental issues regarding the dust generated from the electric arc melting furnace. The arc furnace dust being captured is hazardous for hexavalent chromium. The foundry is a state-of-the-art facility that can produce heat of up to 120 metric tons using a large electric arc furnace.

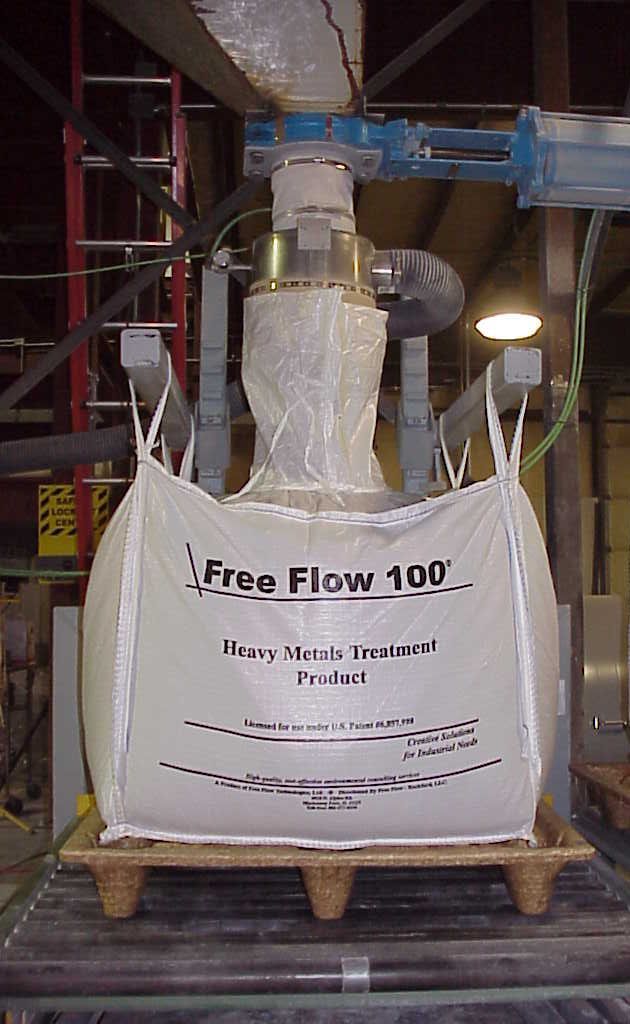

Free Flow visited with plant personnel to ensure that the treatment system was properly designed to meet the current and future needs of the foundry. The final Free Flow system design was custom tailored to meet the customer's space requirements and instrumentation/data gathering requirements. The system utilizes a bulk bag un-loader to supply the volumetric feeder with treatment reagent. From the volumetric feeder, the reagent falls into an educator where the reagent is injected directly into the dust collector ductwork near the melting furnace. Free Flow Technologies, Ltd. was awarded the contract to perform the turn-key installation on the reagent (Free Flow 100®) feed system for treatment of the melt dust and fumes generated from the facility's large electric arc melting furnace.

In January 2013, Free Flow completed the installation of the reagent feeding system. Free Flow personnel worked closely with plant management and maintenance personnel regarding equipment installation with an engineer present at the facility for equipment start-up.

Free Flow also performed the system calibration and presented the maintenance superintendent with a calibration graph for the volumetric feeder. The end result was the treatment system was installed in a timely manner and under budget with effective treatment results.

Free Flow can provide in-house design and turnkey installation of treatment systems for various waste treatment applications and is experienced in providing upgraded systems to allow retrofits regardless of the treatment reagent being utilized. Call us today for more information.

Share On: